All three pouches are made on a Horizontal Form, Fill, and Seal machine (HFFS). 3 & 4-sided sealed pouches encompass everything from a sugar packet, to a single serve drink/supplement mix, up to a dip mix or gravy pouch.

Stand-up gusset pouch (SUP) is exactly as it sounds. These are made to stand up and self display while reducing the amount of packaging materials needed. These are very popular in the baking mix and the multi serve drink mix world. Sizing can range from a 4oz fill to around a 2 pound fill depending on the product. They can also have a zipper closure to keep product freshness and integrity.

This sheet comes on a roll and is universally referred to as "film or roll stock". The alternative is pre-made bags, which we have the capabilities to do, however film or roll stock is the most cost effective way. Pre-made bags require higher minimums, in most situations the reduction in cost will usually make up for it.

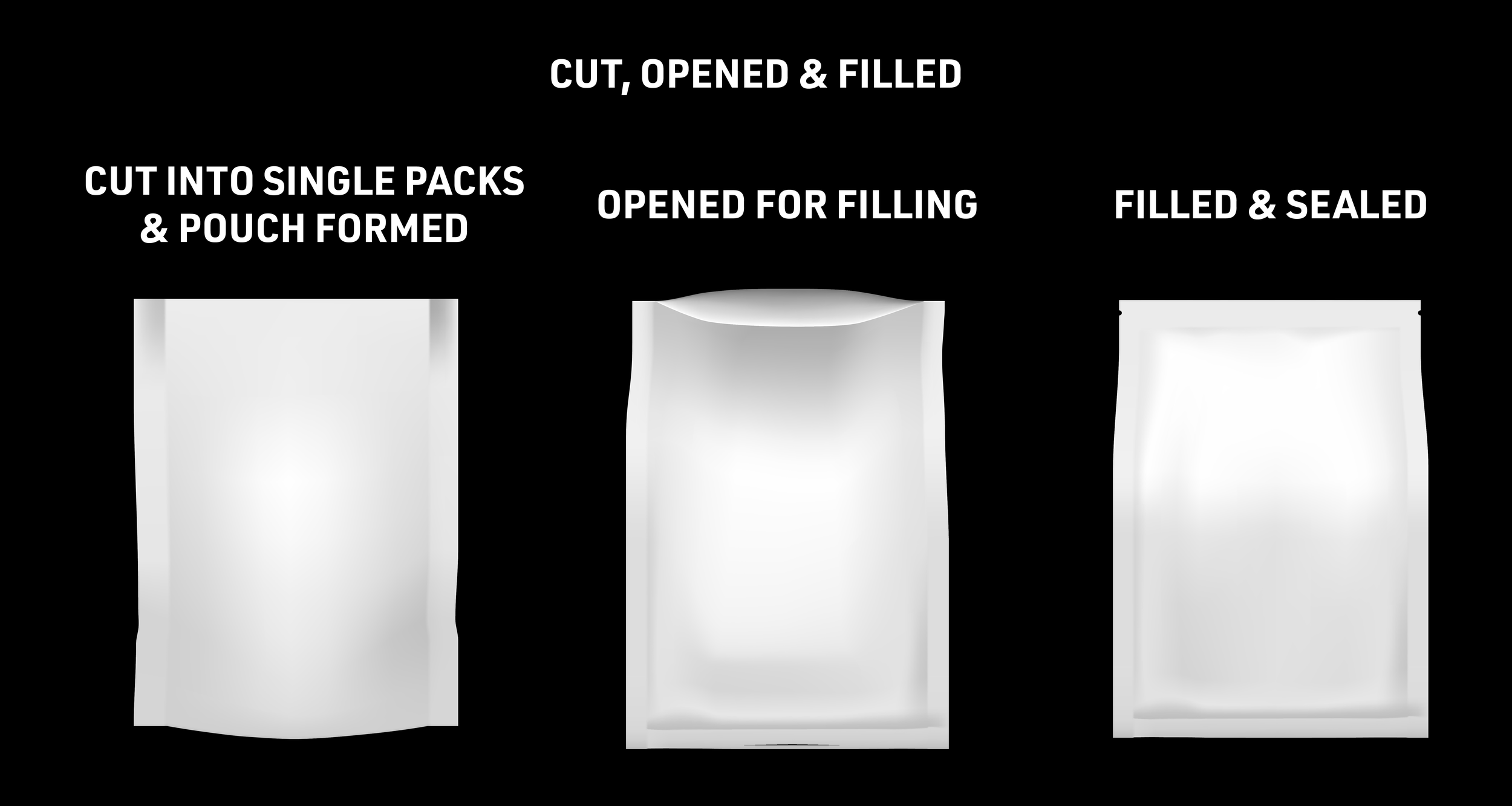

Film or roll stock is formed in the machine. 3 & 4 side pouches are folded over while SUPs are plowed on the bottom to give them their signature "stand-up" feature.

This is where the HFFS machine gets it's name. The film will get slit and the sides will be sealed to form the pouch. After that it will go to a filling station and be completely sealed.

Secondary package and fulfillment configurations are processed. Then put into master cases, palletized, and wrapped, becoming finished shippable goods.